Experiencing sluggish, jerky shifts, grinding when selecting certain gears, or complete transmission failures to engage? These frustrating and dangerous symptoms often indicate a common issue in aging Jeep Grand Cherokees – failing shift solenoids and Jeep Grand Cherokee Shift Solenoid Problems.

Over time, these essential electro-mechanical valves can wear out, become contaminated, or develop electrical faults that hinder smooth gear changes.

Ignoring worsening shift quality can accelerate transmission wear, lead to breakdowns, and result in expensive repairs. However, a proper solenoid diagnosis and strategic rebuild can resolve these Jeep Grand Cherokee shift solenoid problems, breaking the cycle of issues.

This guide delves into the different modes of solenoid failure, from basic wear and tear to more complex hydraulic or sensor issues.

Most importantly, you’ll discover precise transmission solenoid troubleshooting steps and targeted solutions to restore your Jeep’s performance.

So, without further ado, let’s dive in!

What Are Shift Solenoids and How Do They Work?

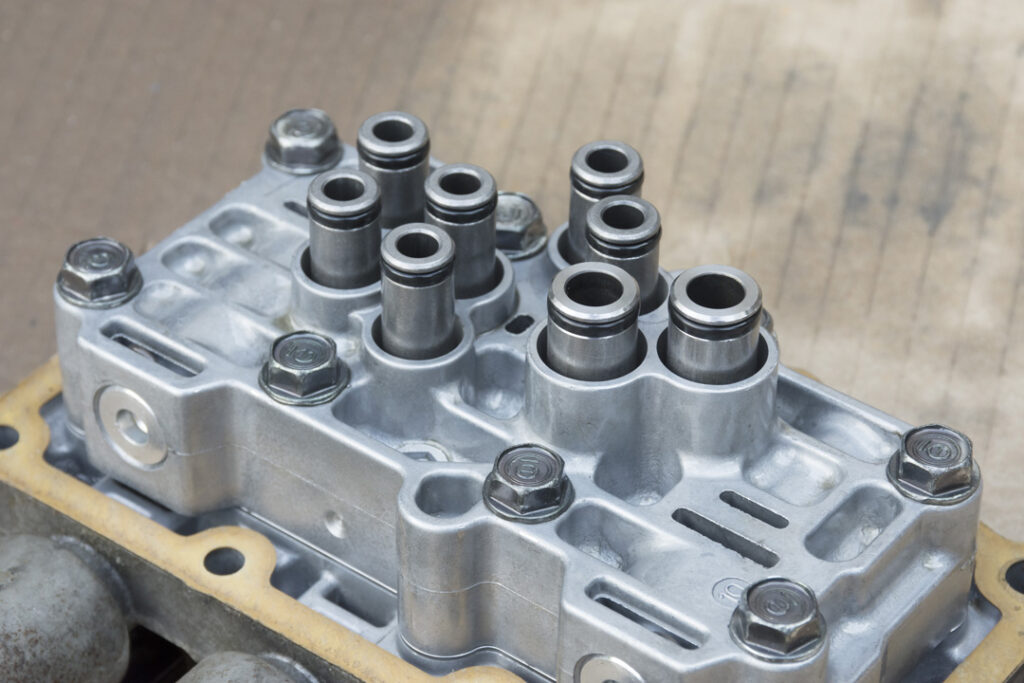

Shift solenoids are electro-mechanical valves that control the flow of transmission fluid into specific passages to change gears. They serve as the interface between your gear lever and the gear sets within the transmission.

Most modern automatic transmissions, including those in some Jeep Grand Cherokee models, use multiple shift solenoids—up to six in total. Each solenoid regulates fluid flow for a specific gear change.

These solenoids are controlled by electrical signals from the transmission computer, which takes into account the gear selector position, throttle input, and other sensor data.

For instance, Solenoid A might be responsible for shifting from 1st to 2nd gear, while Solenoid B manages the shift from 2nd to 3rd. If Solenoid A fails, you may have trouble engaging 2nd gear, but 3rd gear would still function properly because it is controlled by Solenoid B.

When activated, a solenoid valve opens a passage that directs fluid into clutch packs, bands, and other components to engage the specific gear ratio.

Problems occur when solenoids or related valves stick open or closed due to contamination, wear, or electrical faults.

7 Causes and Fixes for the Jeep Grand Cherokee Shift Solenoid Problems:

Jeep Grand Cherokee Shift Solenoid Problems: Diagnosis and Solutions

Shift solenoid issues in a Jeep Grand Cherokee can arise from various causes, including worn-out valves, contaminated fluid, electrical faults, or sensor problems sending incorrect signals. Pinpointing the root cause requires expert transmission diagnostics and methodical troubleshooting. Experienced technicians, particularly those specializing in Jeeps, can efficiently identify and resolve these issues.

Common Causes of Jeep Grand Cherokee Shift Solenoid Problems

1. Physical Damage and Wear

- Cause: Over time, the internal components of shift solenoids wear out due to constant hydraulic forces and electromagnetic fields. Contaminants in the transmission fluid also erode internal parts, leading to sticking valves and poor sealing.

- Troubleshooting: Conduct a road test to detect issues such as flares or slips during shifts. Inspect the solenoid electrical connectors for cracks or damage and examine the transmission pan for signs of wear.

- Solution: Replace the solenoid with a new or remanufactured one to restore critical sealing surfaces, springs, valves, and electrical contacts. Perform a thorough fluid exchange to remove contaminants.

2. Contaminated Fluid

- Cause: Automatic transmission fluid (ATF) can become contaminated with metal shavings, water, acidic byproducts, and carbon deposits over time. This contamination affects fluid flow and solenoid function.

- Troubleshooting: Inspect the transmission dipstick for darkened fluid and drain a sample to check for metal particles or a burnt odor. Monitor pressure readings with external gauges.

- Solution: Perform a comprehensive ATF exchange and install premium synthetic transmission fluid. Replace worn solenoids and seals to eliminate sticking valves and leaks.

3. Electrical Issues

- Cause: Shift solenoids rely on electrical signals from the transmission computer. Wiring, connector, or solenoid winding issues can lead to activation problems and shifting delays.

- Troubleshooting: Inspect wiring harnesses, connectors, and pin contacts for corrosion or damage. Use a digital multimeter to check solenoid resistance and voltage values.

- Solution: Repair or replace any faulty wiring or connectors. Install new solenoids with fresh windings to ensure reliable valve activation.

4. Sensor Problems

- Cause: Transmission sensors monitor speed, position, pressure, temperature, and throttle inputs. Faulty sensors or computer issues can disrupt solenoid function and cause erratic shifting.

- Troubleshooting: Scan for diagnostic trouble codes and graph sensor values during test drives. Inspect for loose connections or damaged sensors.

- Solution: Replace faulty sensors to restore accurate data to the transmission computer, allowing normal solenoid control.

5. Hydraulic Control Issues

- Cause: Shift solenoids require hydraulic force to engage gears. Pump failures, leaks, or control circuit clogs can prevent adequate pressure for solenoid activation.

- Troubleshooting: Scan for pressure-related trouble codes and use external gauges to monitor pressure during road tests. Inspect seals, gaskets, and control valves for wear.

- Solution: Replace leaky seals, worn pumps, or faulty control valves to restore proper line pressure.

6. General Transmission Wear

- Cause: Significant internal wear in an aging transmission can affect shift solenoids’ performance. Issues such as excessive slack in bands, sticky valves, or worn clutch plates hinder smooth shifts.

- Troubleshooting: Scan for multiple system faults or conduct thorough road testing to identify problematic shifts. Check for metallic debris on the transmission pan magnet.

- Solution: Perform a comprehensive transmission overhaul, renewing pumps, clutches, bands, valves, and seals, along with the shift solenoids.

7.Transmission Slipping

- Cause: If the transmission slips between gears or has difficulty staying in gear, it may indicate a problem with the shift solenoids.

- Troubleshooting: Use an OBD2 scanner to retrieve error codes related to the transmission. Specific codes can help pinpoint which solenoid is malfunctioning.

- Solution: Top off or replace the transmission fluid. Access the transmission pan to clean the solenoids and inspect for damage, replacing any faulty solenoids identified by the diagnostic codes. Reassemble the transmission, ensuring the pan gasket is in good condition, and refill with the correct fluid. Reset the Transmission Control Module (TCM) by disconnecting the battery for 10-15 minutes. After reconnecting the battery, conduct a test drive to monitor shifting and check for leaks. Finally, clear any error codes with the OBD2 scanner and verify the issue is resolved. Addressing Jeep Grand Cherokee shift solenoid problems promptly and accurately is crucial to maintaining optimal vehicle performance. By understanding the common causes and solutions, drivers can effectively diagnose and fix these issues, ensuring reliable and smooth shifting.

The Signs of a Bad Shift Solenoid?

Common Symptoms of the P0751 Code?

What Does it Cost to Replace a Solenoid on a Jeep Grand Cherokee?

How Can I Test a Shift Solenoid?

Disconnect the solenoid’s electrical connector and then probe the terminals with the multimeter leads.

Compare the measured resistance value with the manufacturer’s specifications to determine if the solenoid is working properly.

Conclusion

Multiple faults can manifest similar drivability issues in any complex mechanical system. Regardless of the root cause behind your Jeep Grand Cherokee shift solenoid problems, accurate diagnosis and strategic rebuild procedures are crucial for long-term resolution.

Methodical troubleshooting helps pinpoint problems, while road testing replicates specific symptoms. This allows technicians to recommend the optimal combination of rebuilds, component replacements, and upgrades tailored to your Jeep’s needs.

From quick external solenoid refreshes to complete transmission overhauls, professional services can reliably restore shift performance.

Don’t tolerate dangerous drivability issues or incur repeated, costly repairs due to solenoids or sensors. Seeking experienced transmission experts for inspection and repair quotes is highly recommended to ensure your Jeep Grand Cherokee operates smoothly and safely.