Every driver dreads getting into their Jeep Compass, turning the key, and being met with nothing but a service ESC system warning ( Service ESC System Jeep Compass Won’t Start ).

This indicates that the electronic stability control system has detected a severe fault and has disabled the starter motor as a protective measure, leaving you stranded.

With no check engine light or diagnostic codes to guide you, identifying the root cause within the Compass’s complex network of sensors and computers can feel nearly impossible.

However, what if the service ESC system issue preventing your Jeep Compass from starting is a common problem, often caused by a few specific factors?

You can pinpoint the real issue by systematically analyzing wheel speed sensors, wiring faults, controller calibration errors, and other problematic components, and resolve the problem by troubleshooting each potential cause.

Even better, this guide offers easy-to-follow repair tips, reset instructions, and step-by-step tutorials to get your Jeep Compass up and running again.

So, no need to panic the next time the ESC prevents your Compass from starting – simply use this resource to restore normal operation.

Overview of the Service Electronic Stability Control System

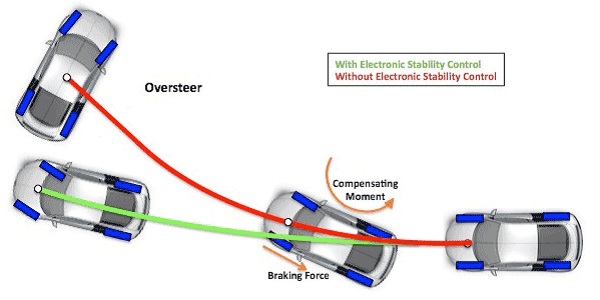

The Electronic Stability Control (ESC) system is a sophisticated technology designed to enhance vehicle stability and safety during maneuvers.

Building on antilock brake systems, it applies brakes to individual wheels and reduces engine torque when it detects a loss of traction.

In the Jeep Compass, the ESC system uses various sensors to constantly compare the steering wheel angle with the actual direction of the vehicle.

When it detects oversteer or understeer conditions, it brakes individual wheels and/or reduces throttle to help keep the Compass on its intended path.

Why does the ESC Matter for Safety?

The National Highway Traffic Safety Administration has found that ESC systems reduce fatal single-vehicle crashes by 30% and all fatal crashes by 35%. This life-saving technology helps drivers maintain control in critical situations, such as emergency lane changes or navigating slippery surfaces.

Additionally, the insurance industry has documented significantly lower property damage claims for ESC-equipped vehicles, as this advanced stability feature reduces the likelihood of spin-outs and off-road accidents.

The Key Components of the Compass ESC System

The seamless operation of electronic stability control relies on the interaction between several vehicle components and sensors:

The seamless operation of the electronic stability control in the Jeep Compass relies on the interaction between several vehicle components and sensors:

- Steering Angle Sensor: Determines the exact steering wheel position and inputs it to the ESC computer, comparing it to the direction of travel.

- Wheel Speed Sensors: Mounted at each wheel, these sensors read rotational speeds. Any difference between the left and right indicates slippage.

- Lateral Accelerometer: Measures side-to-side forces on the vehicle body during maneuvers.

- Longitudinal Accelerometer: Senses front/rear vehicle acceleration for traction data.

- ESC Control Unit: The computer brain that analyzes sensor data and activates/modulates ESC.

- Hydraulic Unit: Contains valves to regulate brake fluid pressure at each wheel upon ESC activation.

- Vehicle Dynamics Control: Integrates ESC, rollover mitigation, hill start assist, and trailer sway control.

The Impact of ESC System Issues

Issues with sensors or communications within the stability control system can lead to a range of problems:

- Disable the ESC system and its associated safety benefits

- Prevent the Jeep Compass from starting or cause it to stall

- Result in a rough-running engine or reduced power

- Cause poor transmission shifting

- Create conflicts with other integrated features

It’s crucial to troubleshoot and resolve ESC faults promptly to prevent further impact on other vehicle systems. Understanding this technology is the first step toward diagnosing and fixing issues related to the “service ESC system Jeep won’t start” problem.

Service ESC System Jeep Compass Won’t Start – 7 Causes and Fixes

When the electronic stability control (ESC) system detects certain faults, it may disable the engine from starting as a protective measure. Diagnosing the root cause through methodical troubleshooting is essential for taking corrective action.

Here are a few potential issues that could lead to a no-start condition related to ESC errors:

1. Wheel Speed Sensor Damage

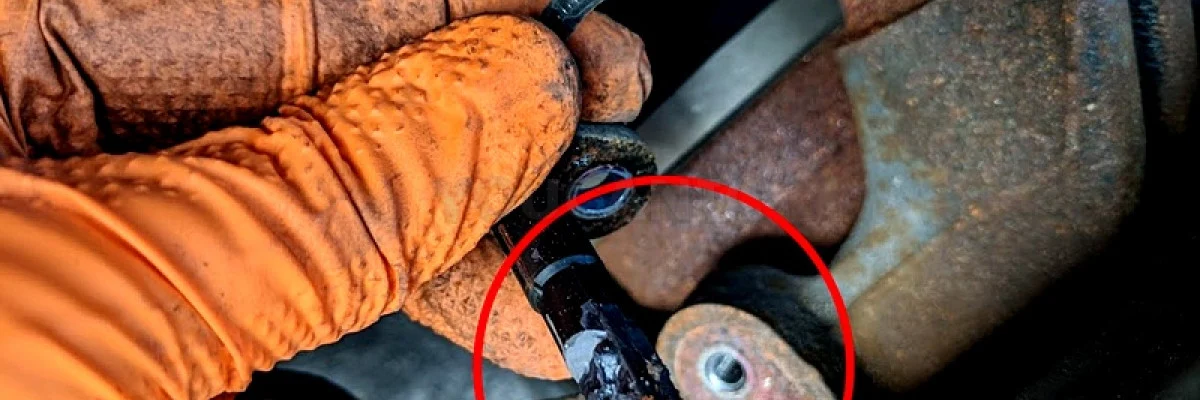

One of the most common causes of ESC-related failure to start is damage to a wheel speed sensor. These sensors, mounted at each wheel, provide critical data on individual wheel speeds to the ESC computer.

Troubleshooting

- Use an OBD2 Scanner: Begin by using an OBD2 scanner tool to retrieve any diagnostic trouble codes stored in the Compass. Pay attention to any sensor fault codes related to the wheel speed sensors (typically C2202 through C2205).

- Visual Inspection: Check the physical condition of sensors at each of the four wheels. Look for rust, corrosion, damage to the sensor body, leaks at the mounting seal, or excessive debris buildup on the tip near the rotor that could interfere with signal quality.

- Check Connectors: Ensure a tight fit by gently twisting and pushing the connector attached to the vehicle wiring harness. Inspect for bent or broken pins.

- Inspect Wiring: Follow the wiring from each wheel speed sensor back along the control arm and up to the ESC module near the center of the vehicle. Look for areas of rubbing or chafing damage that may have shorted or disrupted communication.

Solutions

If a visual inspection reveals any damage to a wheel speed sensor or its associated wiring, replacement of the affected part is necessary.

Replace your Jeep Compass wheel speed sensors on Amazon.

Begin by erasing all diagnostic trouble codes from the Compass ESC system memory using your scanner tool. Next, test the system’s functionality after replacing the sensor and wiring.

Should the no-start issue persist, a comprehensive diagnosis of the other sensors in the stability control system is necessary, including the steering angle, lateral acceleration, and longitudinal acceleration sensors.

2. Steering Angle Sensor Calibration

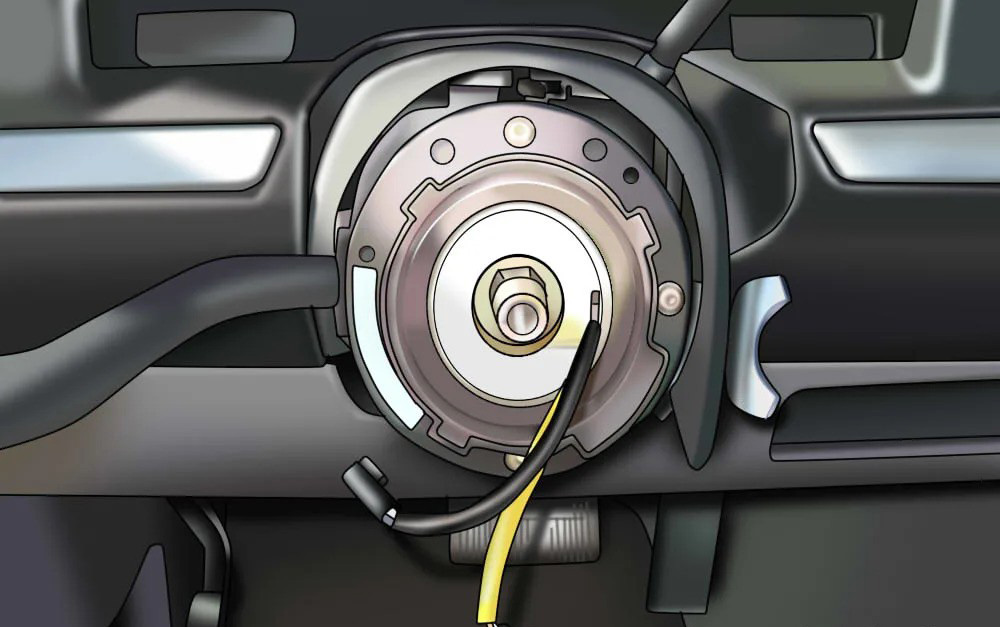

The steering angle sensor (SAS) provides critical real-time information to the Jeep’s ESC module about the exact position of the steering wheel.

If this calibration is incorrect or the sensor malfunctions, it can trigger a failsafe mechanism that prevents the engine from starting.

Troubleshooting

The first indication of issues with the steering angle sensor (SAS) is often through diagnostic trouble codes retrieved via an OBD scanner.

Next, inspect the mechanical condition and electrical connector at the base of the steering column for any signs of damage or a loose fit.

With the ignition turned to the ON position (but without starting the engine), use the scanner tool to monitor the raw signal data from the SAS as the wheel is slowly turned from lock to lock.

Any erratic readings or significant signal offsets may indicate the need for recalibration or replacement of the sensor.

Solutions

- If the SAS data appears reasonably smooth during a full lock-to-lock rotation, attempt to recalibrate the sensor using the factory recalibration procedure provided by the manufacturer’s service software.

Get a new steering angle sensor for your Jeep Compass on Amazon.

- After clearing the codes, test for successful engine starts. If the issues persist or the signal output remains unusable, replacing the SAS with a new one usually resolves the problem.

- Ensure that the latest calibration data for the new SAS is loaded during installation.”

3. Faulty Yaw Rate Sensor

The yaw rate sensor, located near the ESC module in the vehicle’s center, functions similarly to the steering angle sensor. It detects slight chassis rotations around the center axis, providing essential data that complements the wheel speed sensors for detecting loss of traction.

Troubleshooting

A faulty yaw rate sensor can disable the vehicle’s starting capabilities, as its data is crucial for ESC system operation. Begin by checking for any related trouble codes.

While you can’t directly inspect the yaw rate sensor, ensure all mounting points are secure. Wiggle the connector with the ignition on to check for intermittent signal dropouts. Compare live scanner data on yaw rate against expected values during gentle left/right vehicle rocking motions. Erratic data indicates internal sensor malfunctions.

Solutions

- If no codes are stored but the yaw rate signal remains erratic, attempt recalibration using the manufacturer’s service software and retest.

- If codes return or values remain significantly out of normal range, replacing the faulty yaw rate sensor usually resolves ESC faults. Be sure to recalibrate the new sensor upon installation.

4. ESC Control Module Failure

Occasionally, internal malfunctions within the electronic stability control (ESC) unit can interfere with its communication with vehicle systems, preventing the engine from starting. The ESC module is responsible for processing data from various sensors and triggering braking or throttle responses when wheel slip is detected.

Troubleshooting

Generic error codes related to the ESC control module are primary indicators of internal faults. Examine all wiring connections to the module for any signs of damage, bent pins, or corrosion that could affect data input.

If external issues are not present, try connecting a known-good spare module and see if the vehicle starts. If the problem persists, it indicates a failed ESC module that needs to be replaced.

Solutions

- First, use an OBD2 scanner to clear any codes from the ESC module memory after installing the new control unit.

- Check if the vehicle starts successfully to confirm the issue is resolved.

- Utilize the manufacturer’s service software to reprogram the replacement module with the vehicle’s VIN and the latest calibration data.

- Finally, perform a road test to ensure the ESC functions correctly before returning the vehicle to its owner.

5. Wiring Harness Damaged

The wiring harness delivers power and data connections between the ESC module, wheel sensors, and vehicle systems like the engine computer. Issues such as damaged or corroded wires in this harness can lead to complete starting failure.

Troubleshooting

Since no specific trouble code may indicate a harness problem, a visual inspection of the wires is necessary. Examine the connectors at the ESC module and the various junction points under the dashboard and near each wheel. Look for signs of corroded or bent pins, damaged insulation, shorts between wires, or areas with heat damage from potential shorts or overloads.

Manipulate the harness while monitoring scanner data to detect any intermittent connections.

Solutions

For minor damage, use electrical tape to repair the harness. Replace individual wires if possible, or the entire harness if multiple circuits are affected. Ensure any splices are soldered and heat-shrunk for durability.

After repairs, clear the ESC codes and power cycle the ignition to verify if the vehicle starts. Conduct a road test to ensure proper functionality.

6. Low System Voltage

The ESC system in the Jeep Compass needs a stable voltage within the normal range of about 12-14 volts to function correctly. Problems with battery cables or a weak battery/charging system dropping below this range can lead to no-start conditions.

Troubleshooting

Since voltage trouble codes might not appear, use a meter to measure the battery voltage directly. With all accessories turned off, the battery voltage should be 12.4 volts or higher in a healthy system.

During starting attempts, if the voltage drops below 10 volts, this indicates a bad battery, poor connections at the terminals or cables, or a failing alternator not maintaining proper system voltage.

Solutions

- Start by cleaning any corroded battery cable connections.

- Perform a load test on the battery and replace it if it is weak or unable to hold a charge. Check the alternator drive belt for slipping and ensure the pulley is tight.

- Finally, test the alternator output and replace it if it cannot maintain the system voltage around 14 volts while the engine is running.

7. Poor Ground Connections

Loose or corroded ground connections can interfere with the ESC system’s electrical flow, causing communication issues that might prevent the engine from starting.

Troubleshooting

Corrosion: Ground connections can become corroded over time, especially in areas exposed to moisture, road salt, or other environmental factors. Corrosion can impede the flow of electricity, leading to communication issues within the ESC system.

Loose Connections: Vibrations from regular vehicle operation can cause ground connections to become loose. A loose ground connection can create intermittent electrical problems, disrupting the ESC system’s functionality and preventing the engine from starting.

Damaged Ground Wires: Physical damage to the ground wires, such as fraying or cuts, can disrupt the electrical circuit. This damage can occur from wear and tear, accidents, or poor maintenance practices.

Improper Installation: During repairs or modifications, ground connections might not be properly reinstalled, leading to poor contact and electrical issues. Improper installation can result in insufficient grounding for the ESC system.

Oxidation: Over time, oxidation can form on metal surfaces of ground connections, creating a barrier that hinders the flow of electricity. This is especially common in older vehicles or those exposed to harsh environments.

Solutions

- Inspect Ground Connections: Start by locating all ground connections related to the ESC system. These are typically found near the battery, on the chassis, and near the ESC module. Visually inspect these connections for signs of corrosion, damage, or looseness.

- Clean Corroded Connections: If you find corrosion, clean the affected areas using a wire brush or sandpaper to remove the corrosion and expose clean metal. Apply a dielectric grease to the cleaned connections to prevent future corrosion.

- Tighten Loose Connections: Use appropriate tools to tighten any loose ground connections. Ensure that all connections are secure and making proper contact with the metal surfaces.

- Repair or Replace Damaged Wires: If any ground wires are damaged, repair them by splicing and soldering new wire segments or replace the entire wire if necessary. Use heat shrink tubing to protect the repaired areas from moisture and further damage.

- Verify Proper Installation: During any repair or modification, ensure that ground connections are properly reinstalled and securely fastened. Double-check connections to confirm they are tight and making good contact.

- Check for Oxidation: If oxidation is present, clean the affected surfaces with a metal cleaner or abrasive pad. Ensure that the cleaned surfaces are free of oxidation before reassembling the connections.

- Test Electrical Continuity: Use a multimeter to test the continuity of the ground connections. Ensure there is a good electrical path between the ground points and the vehicle’s chassis. Poor continuity indicates further cleaning or repair is needed.

- Recheck System Functionality: After addressing the ground connections, clear any ESC-related error codes using an OBD2 scanner. Attempt to start the vehicle and verify that the ESC system is functioning correctly. Conduct a road test to ensure the issue is resolved.

By thoroughly inspecting and addressing poor ground connections, you can restore proper electrical flow to the ESC system, ensuring reliable vehicle starting and operation.

Conclusion

Facing a service ESC system warning along with a no-start situation can quickly turn your day upside down.

However, with the troubleshooting fundamentals and repair tips outlined in this guide, you have the knowledge to systematically diagnose the common causes behind starting failures.

By performing precise repairs to stabilize the electronic stability control system and completing the necessary reset and recalibration procedures, you can clear the check engine light and restore your Compass to normal operation.

There’s no need to panic the next time that warning appears!